AI Actually Needs.

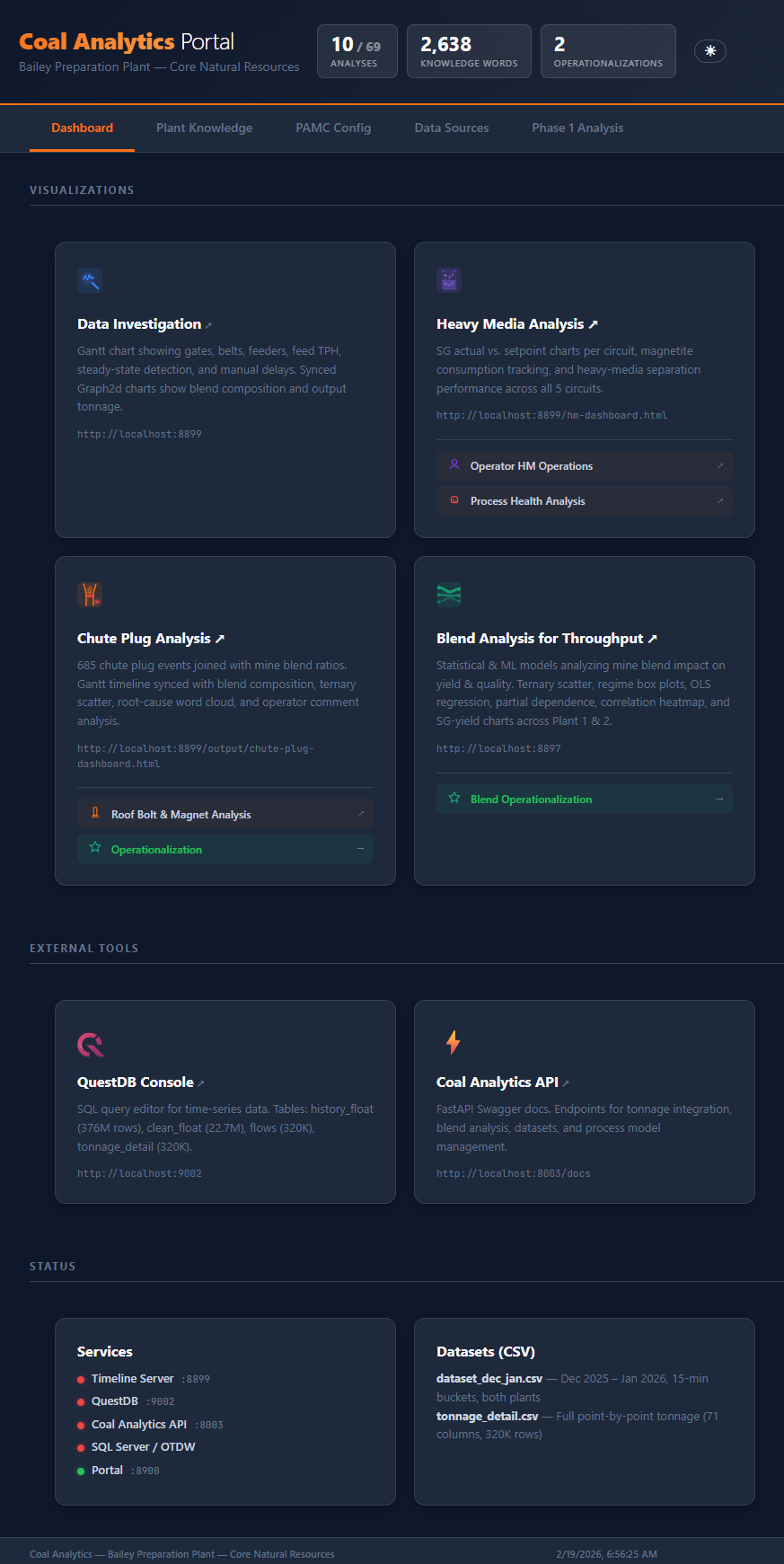

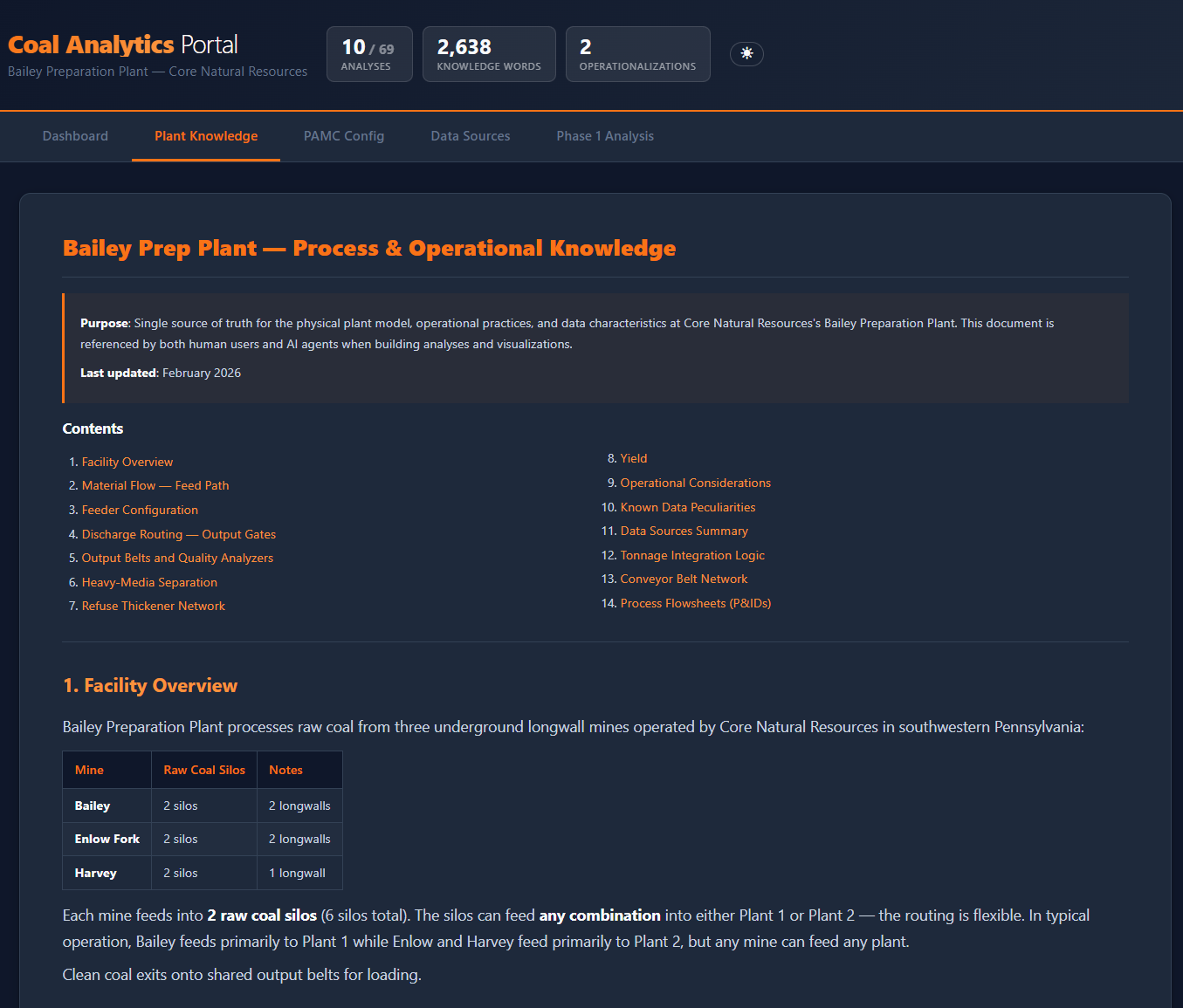

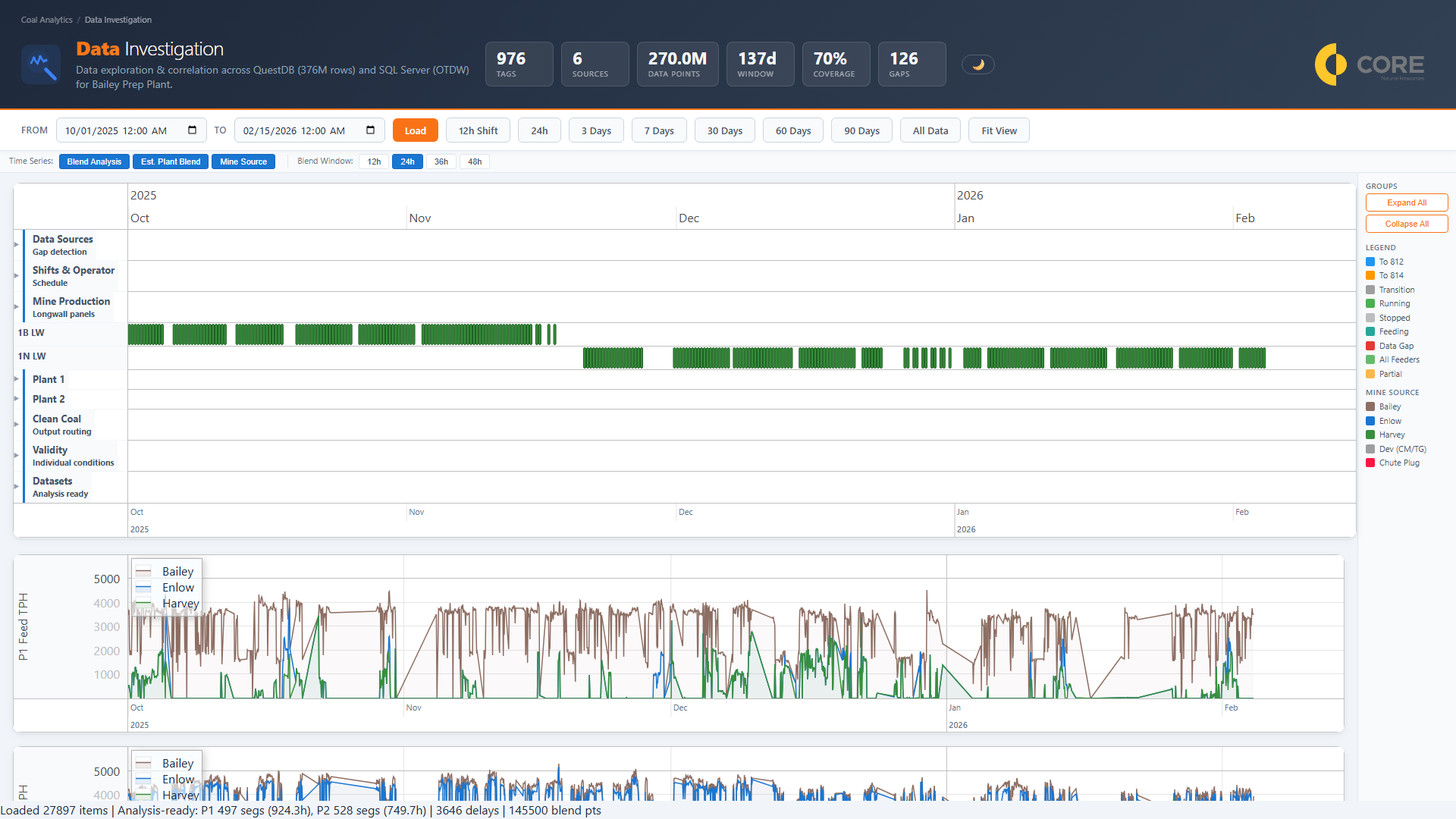

Every AI project needs data. But not just data — the right data, organized correctly, with the right context attached. Most industrial operations have thousands of sensors and years of history. Almost none of it is structured in a way that AI can reason about effectively. TSAI solves that problem.

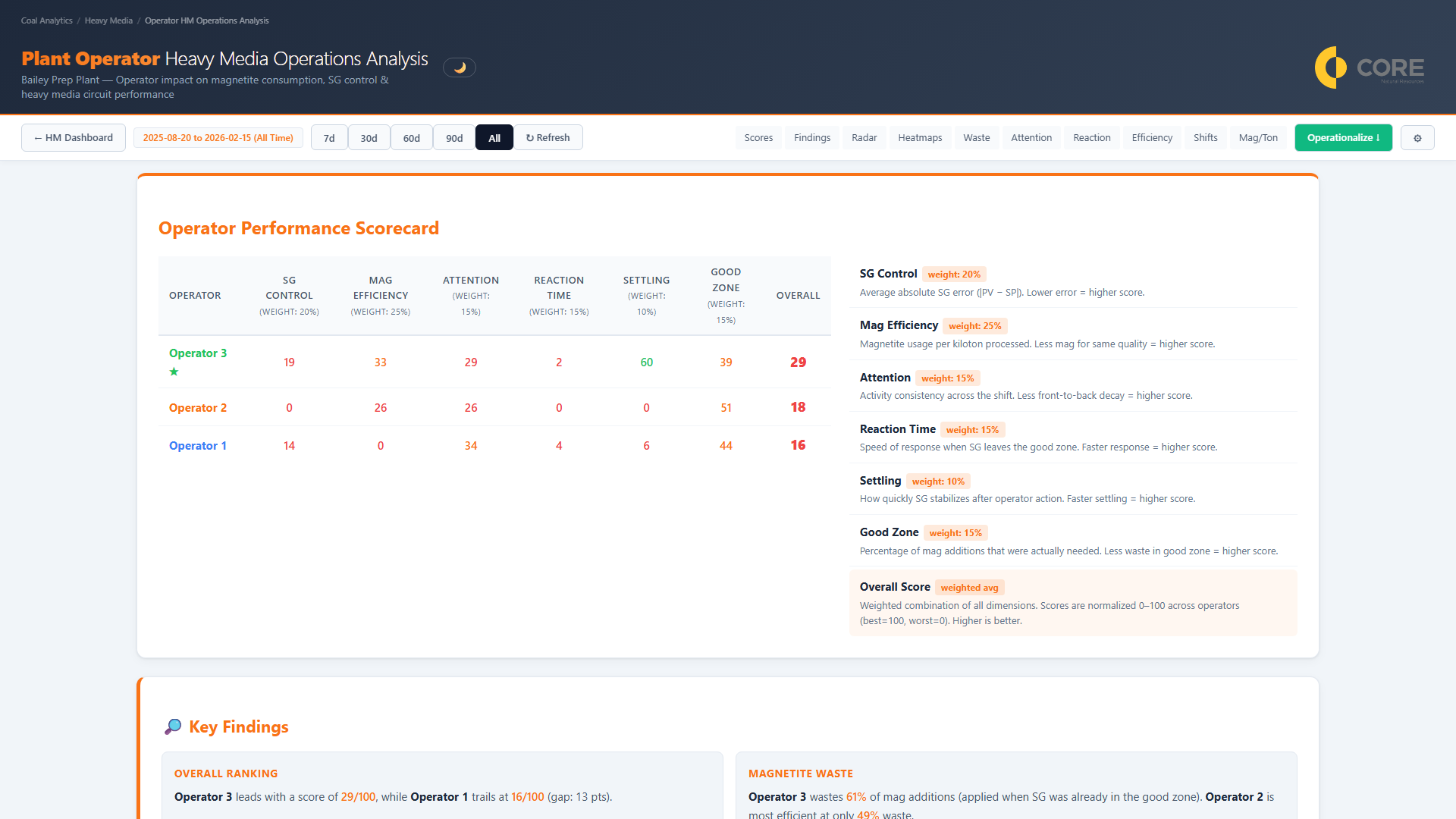

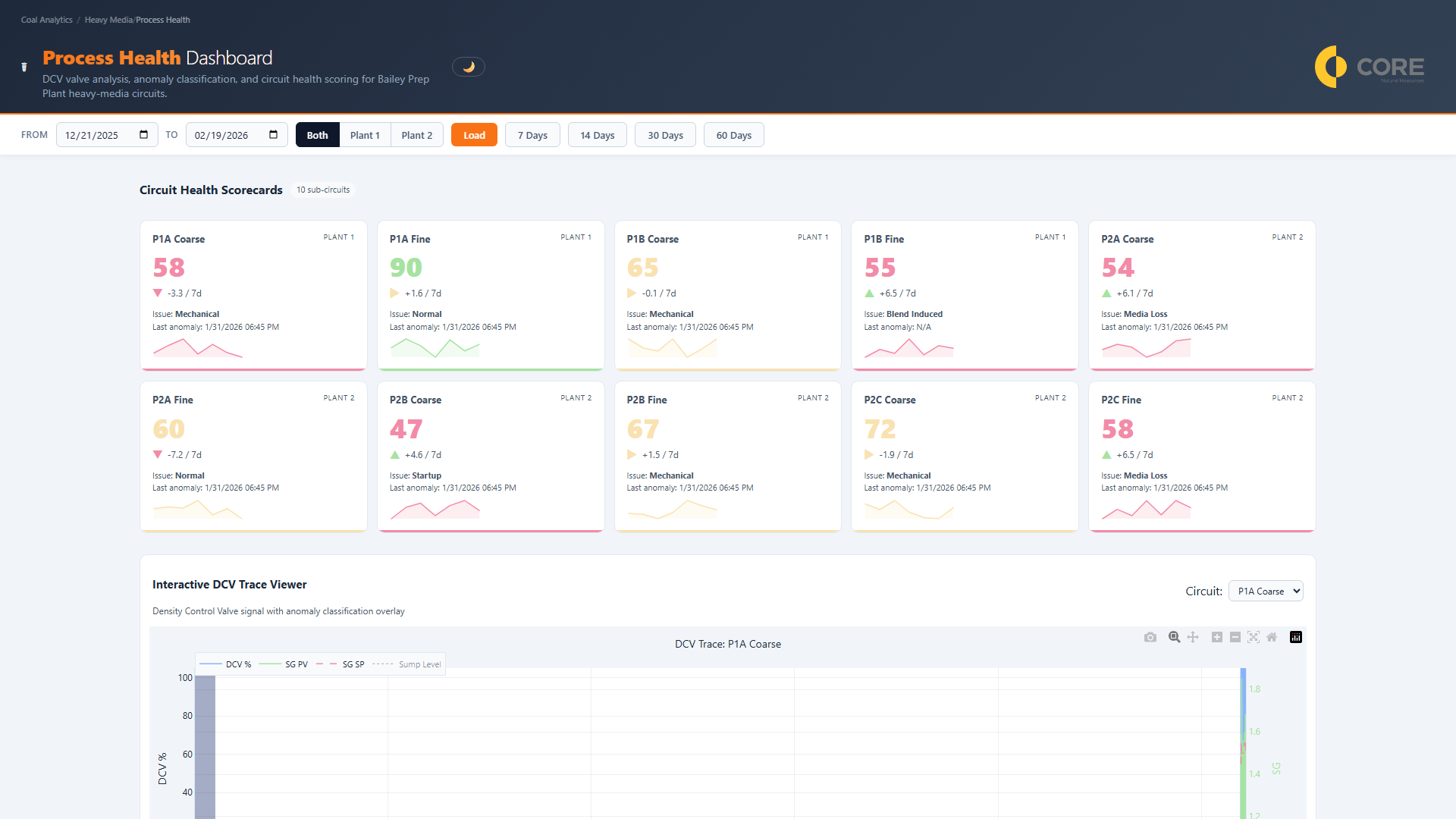

TSAI connects to your existing automation systems and begins capturing operational data in a time-series format purpose-built for AI consumption. But data capture alone isn't enough — the platform is specifically designed to capture the human context that machines can't record on their own.

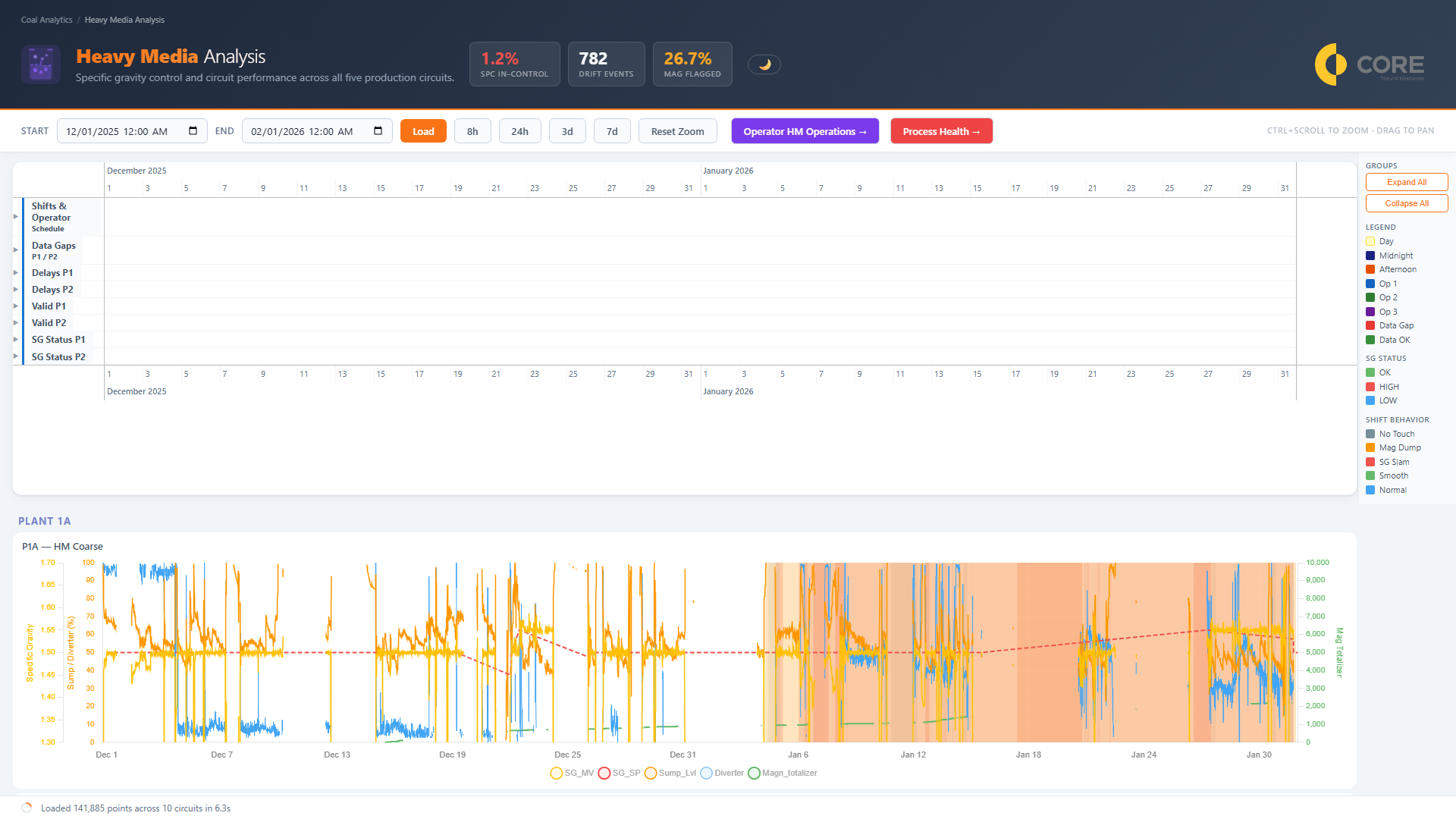

When an anomaly occurs, TSAI detects it. But it also gives operators the ability to annotate what they observed — what changed, why it happened, what they did about it. That human layer is what transforms raw sensor data into something AI can actually learn from.

The result: a living operational record that combines machine precision with human knowledge — structured, contextualized, and ready to feed today's AI tools.

Today's AI is powerful — but it needs context to be accurate. A model that sees a magnetite spike without knowing that Mine A coal was running that shift will draw the wrong conclusion. TSAI captures both the event and the explanation, so the AI has the full picture.

TSAI is not a generic IoT platform adapted for industry. It was designed from the ground up around the operational patterns of preparation plants, longwall operations, and mineral processing circuits — the event structures, the shift rhythms, the tag hierarchies, the delay classifications that matter in this industry.