Platform Workflow

1 — Industry Dashboard

Live KPIs and trend charts from 20+ MSHA datasets, updated weekly.

▸

2 — Internal Data Integration

Your internal EHS records merged with MSHA government data into one picture.

▸

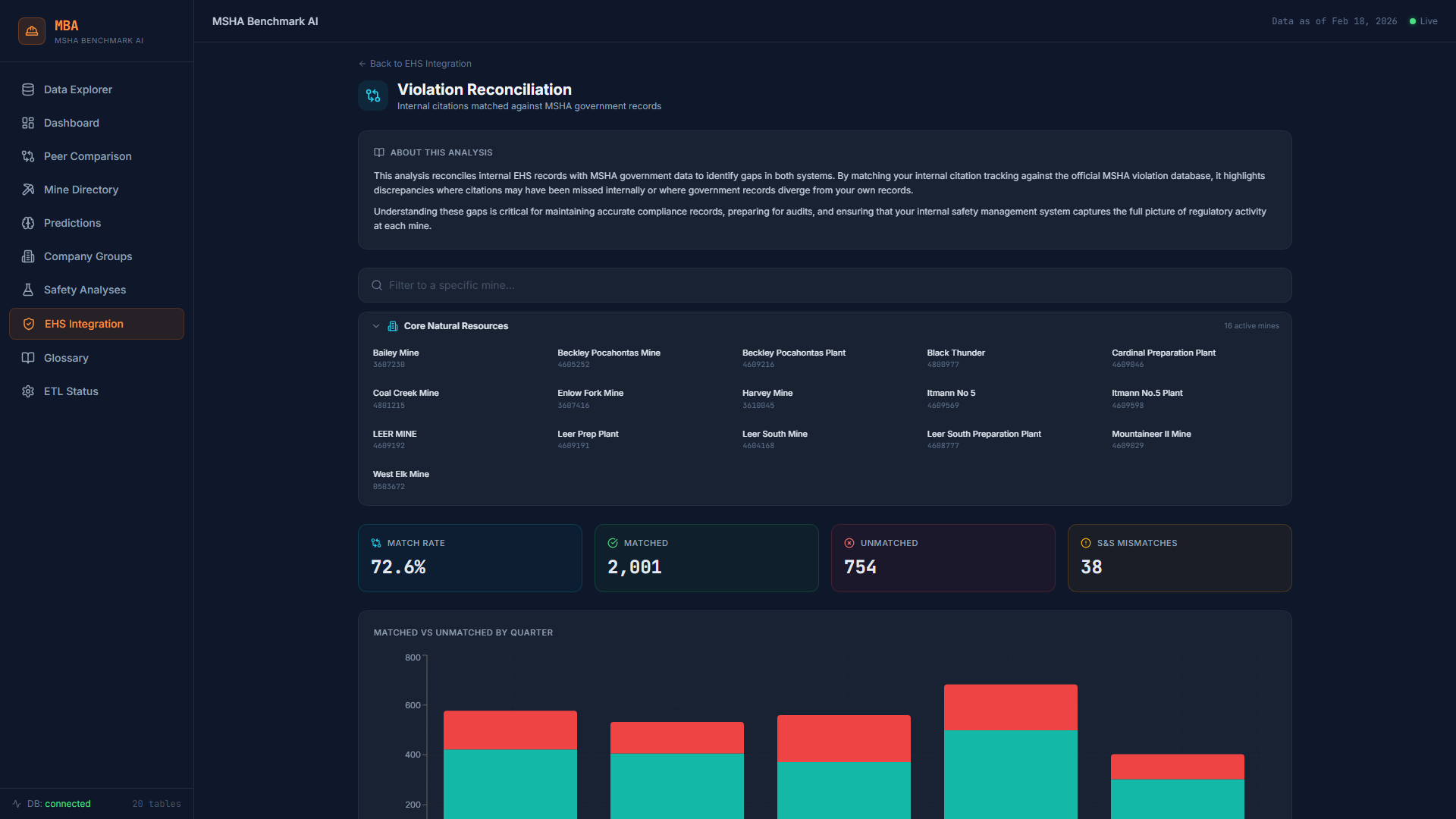

3 — Reconciliation

Match internal citations against MSHA records — identify gaps in both systems.

▸

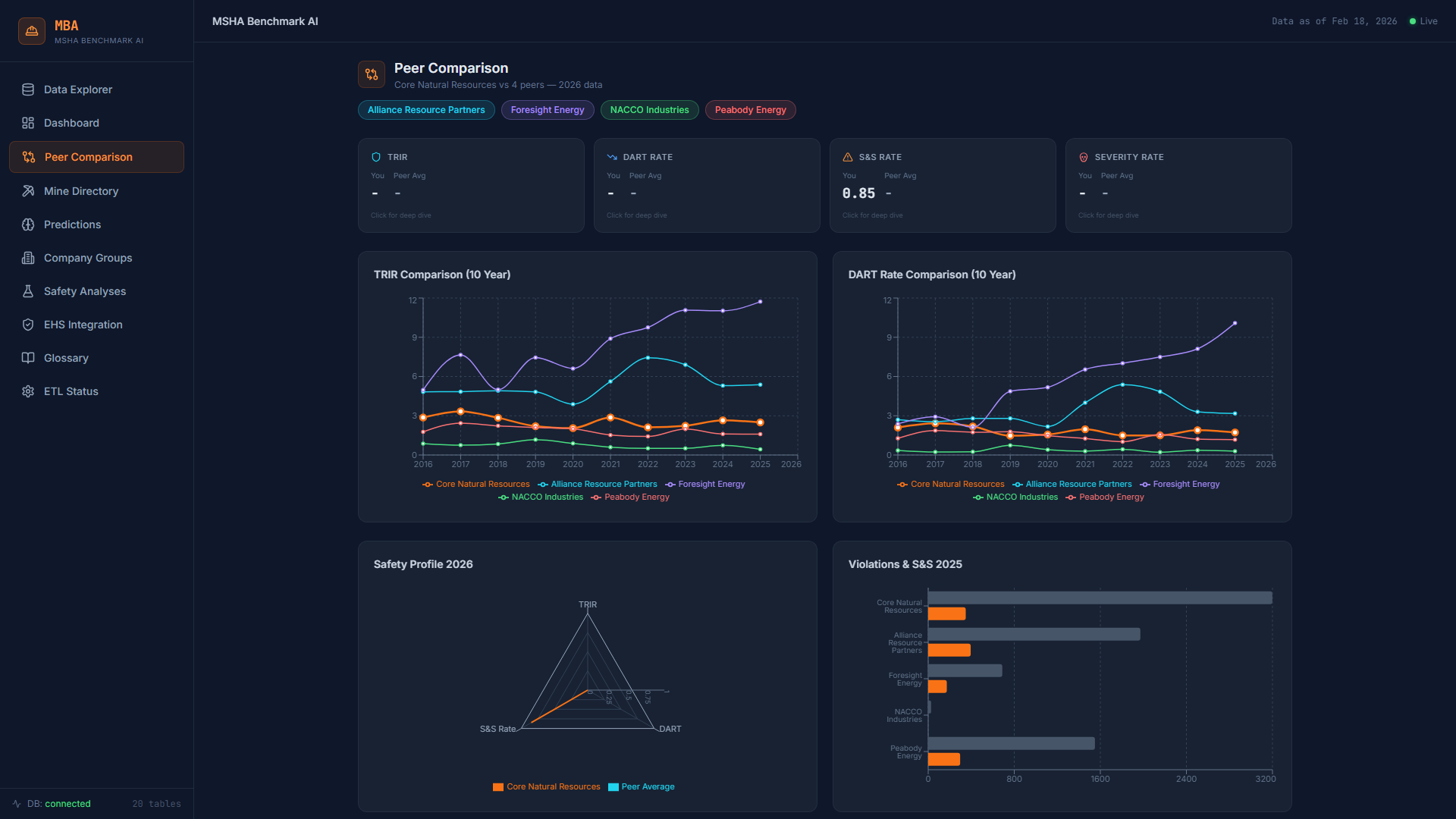

4 — Peer & Internal Benchmarking

Compare your sites internally and against every peer in the MSHA registry.

▸

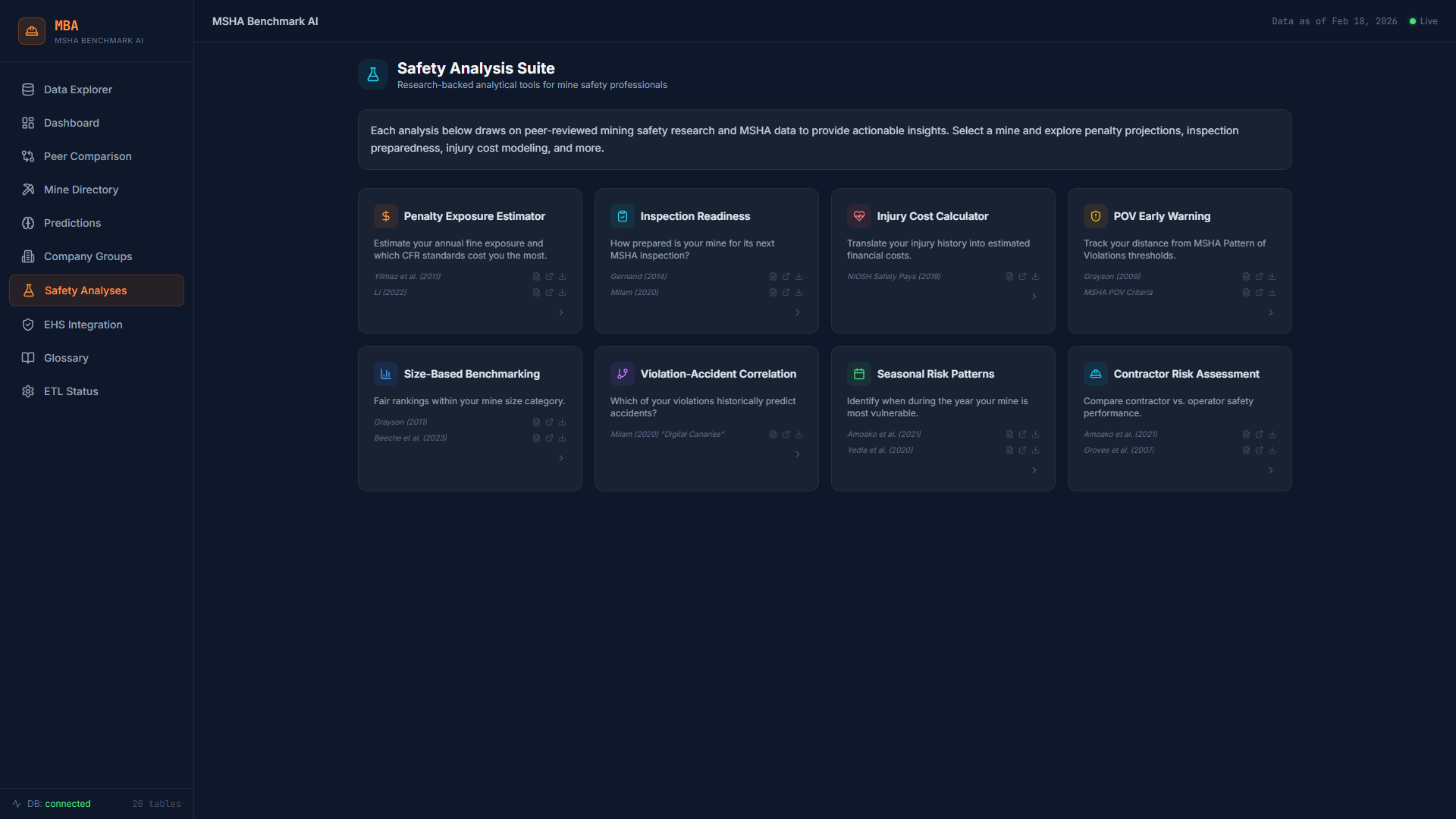

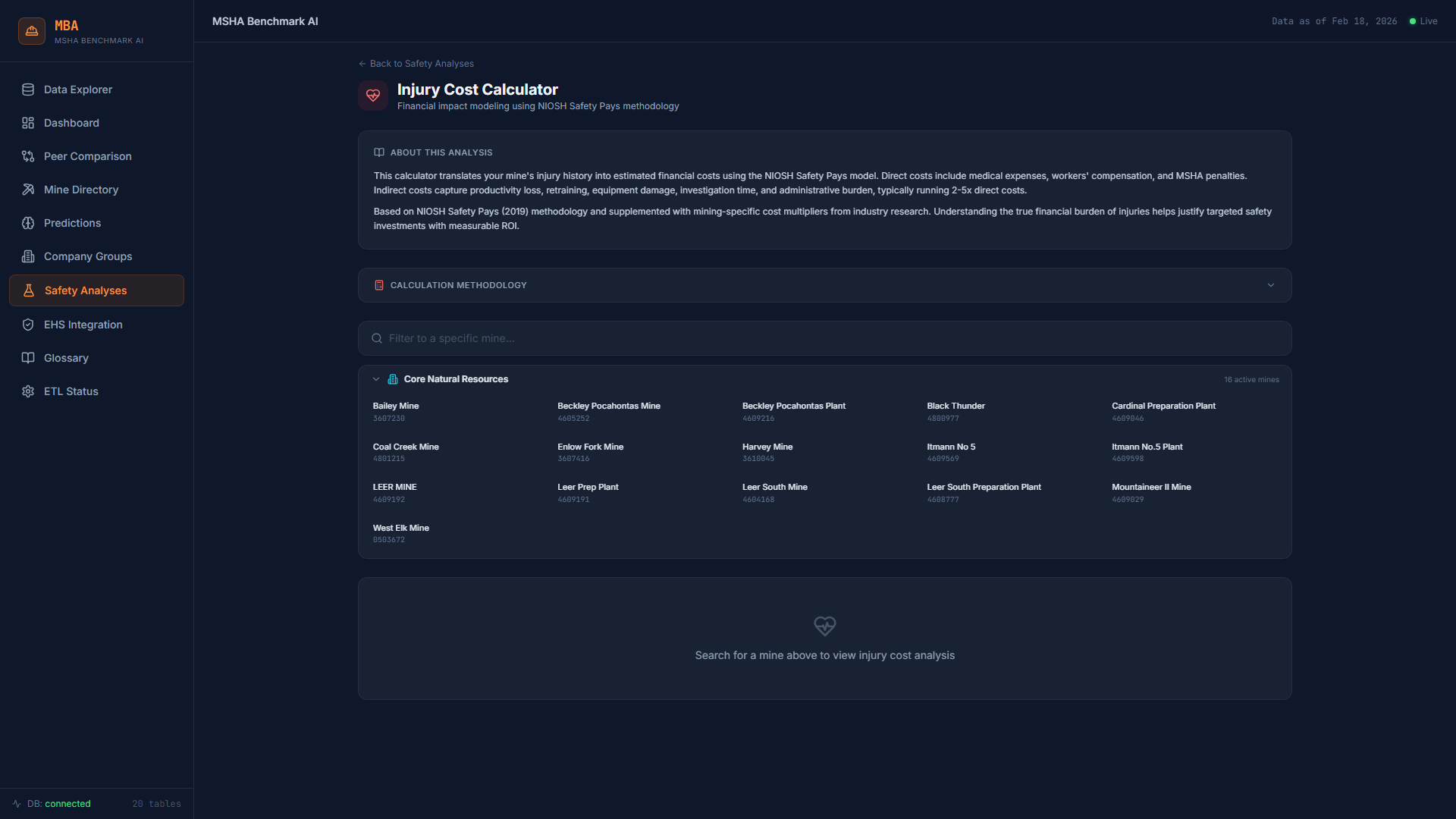

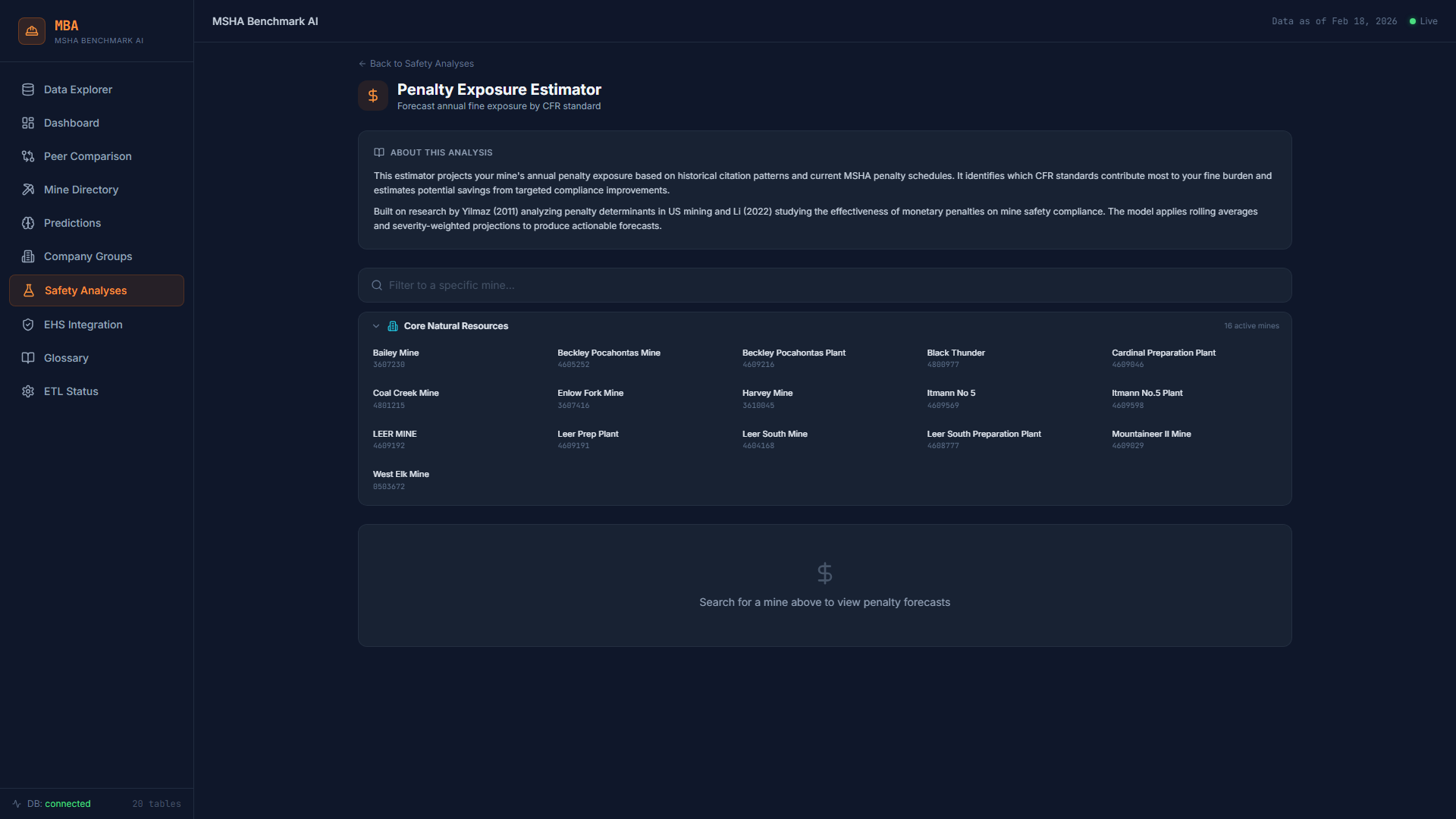

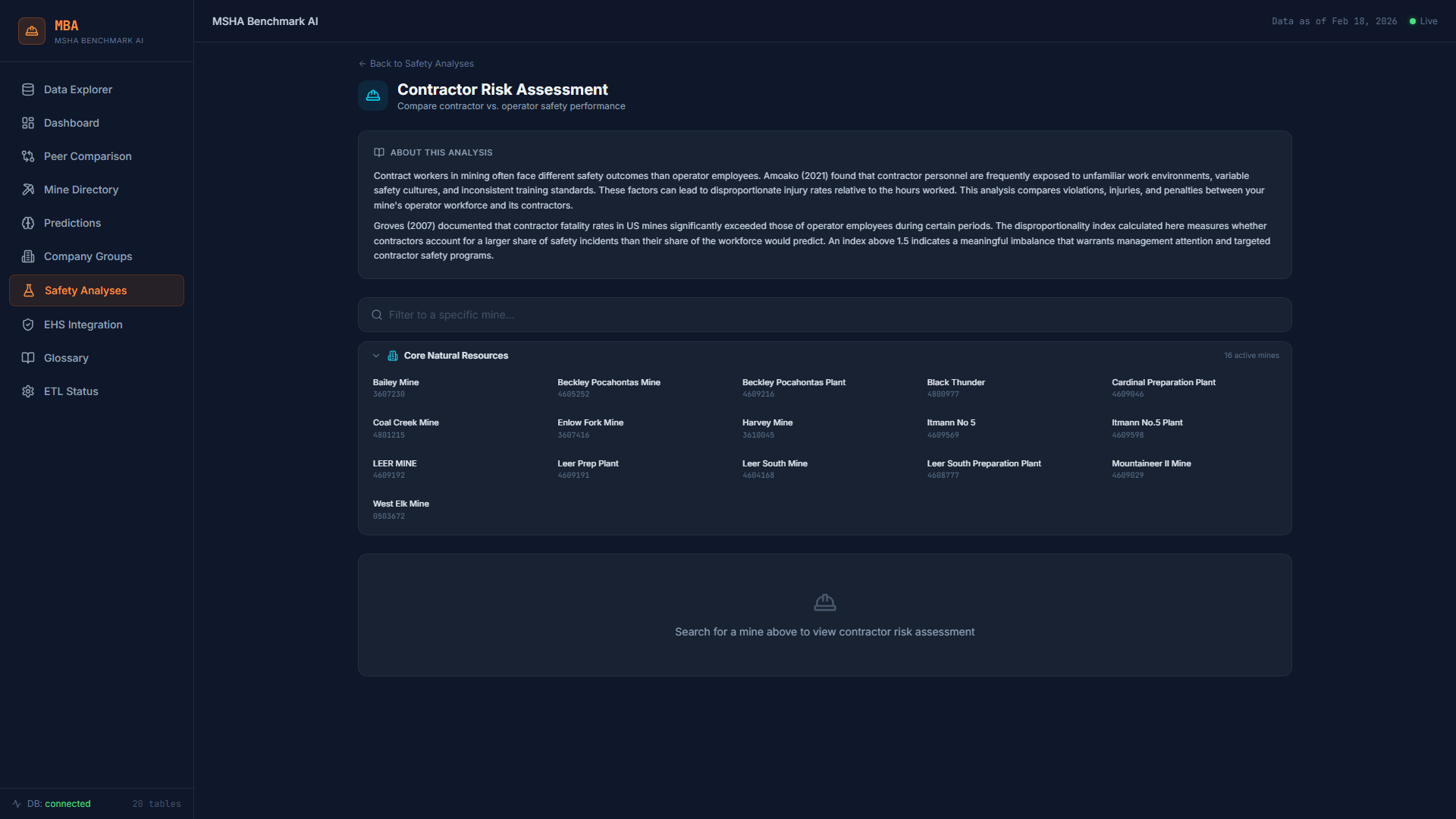

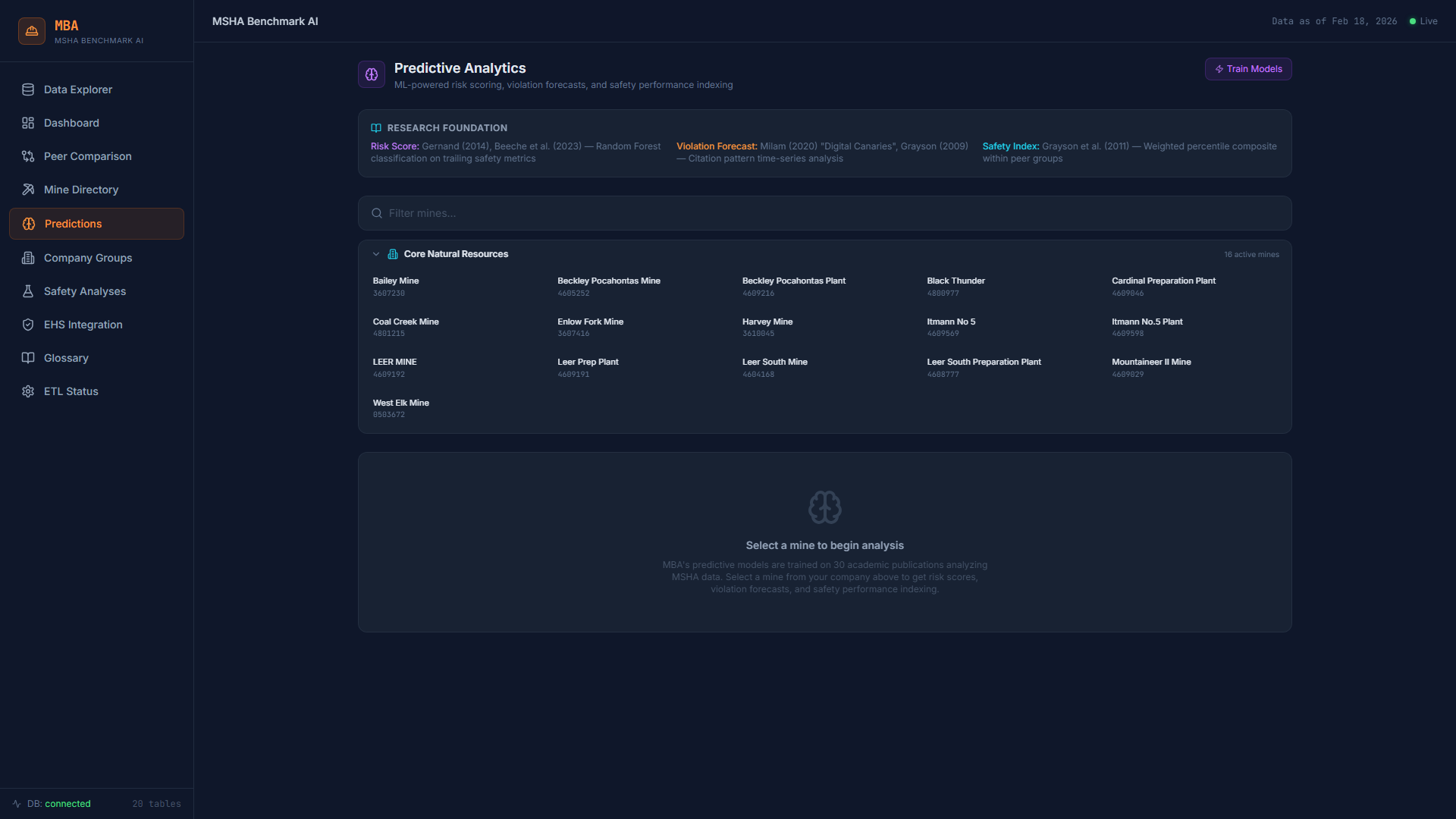

5 — Deeper Analytics

Predictive models, research-backed tools, and AI anomaly detection.