30 Years of Mining AI.

Before It Was Cool.

Dr. Data Mining was built around a simple observation: the mining industry has never lacked for data. It has lacked for people who could turn that data into decisions that stick on the plant floor. Founded by Dr. Sean Dessureault — a mining engineer, serial entrepreneur, and former tenured professor — the company brings together three decades of experience designing, deploying, and supporting data systems in heavy industry.

That experience spans the full cycle. From building the first university research program in mining information technology at the University of Arizona, to founding MISOM Technologies — a mobile app and IoT company that was bootstrapped from consulting, grew through a Series A funding round, and was acquired by MST Global (now Komatsu) in 2017. From serving as VP of Technology and Innovation at The Mosaic Company, scouting and evaluating emerging technology across global operations in Florida, Saskatchewan, Brazil, Saudi Arabia, and Peru — to building Dr. Data Mining as the culmination of everything learned along the way.

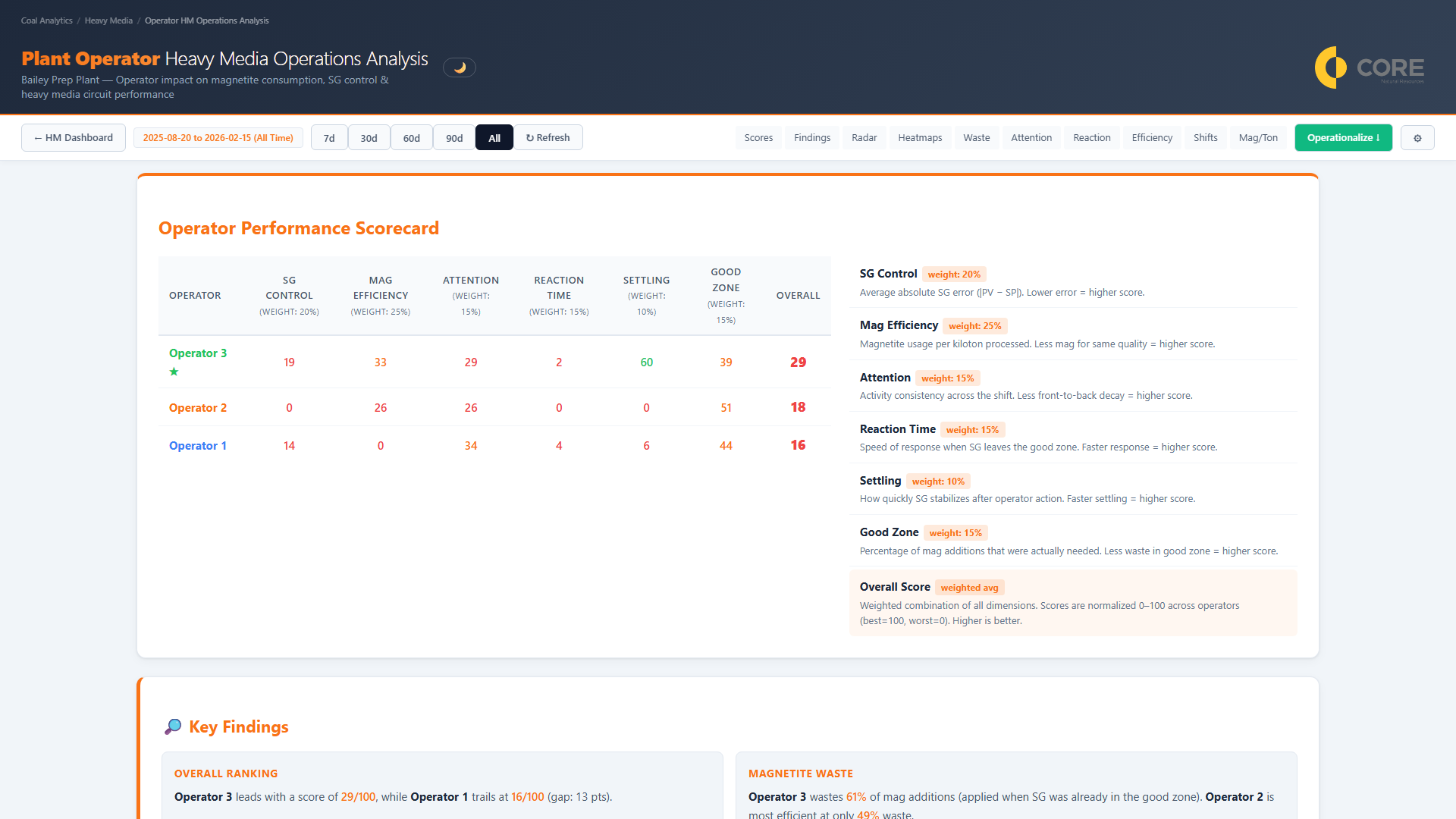

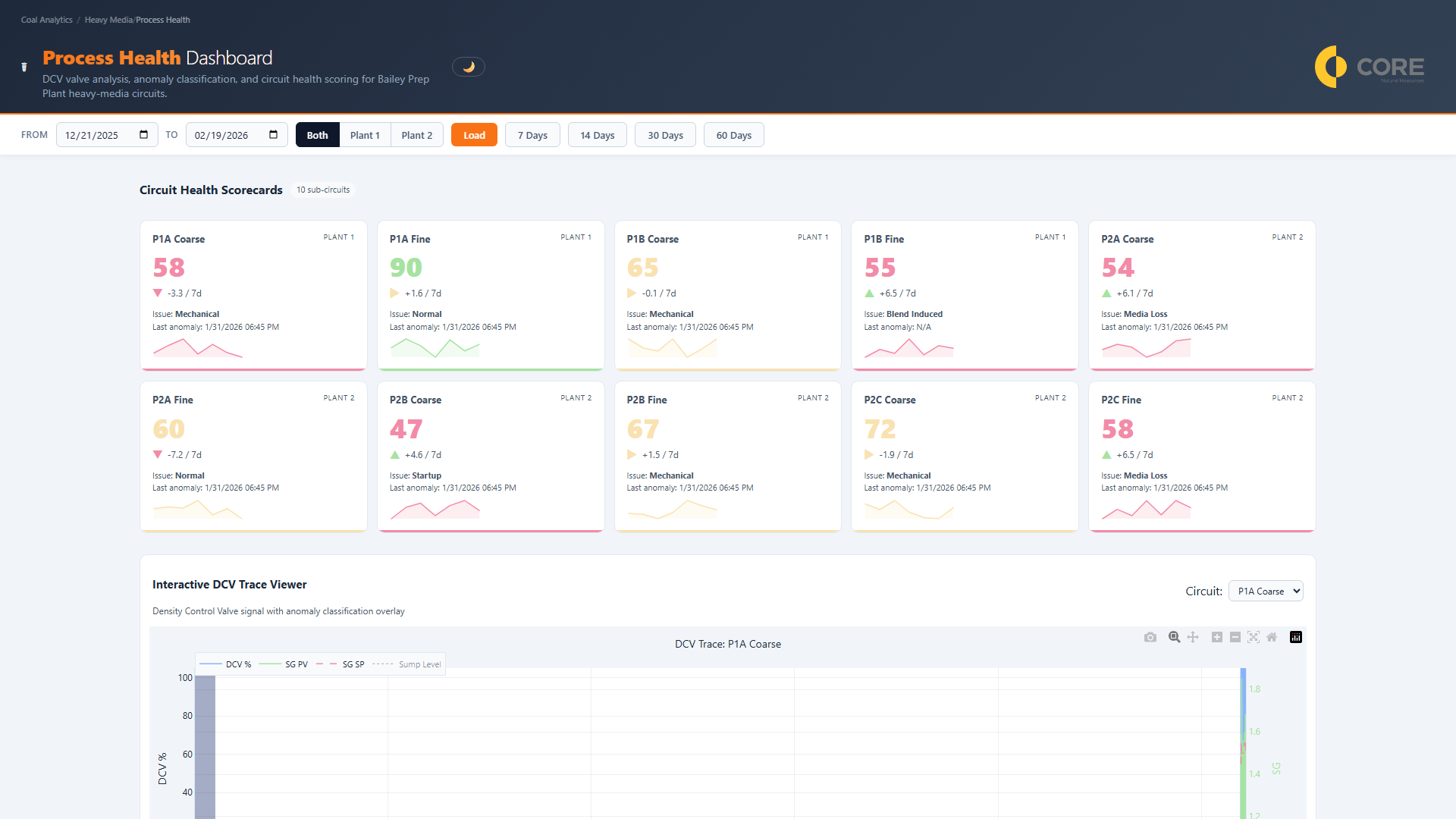

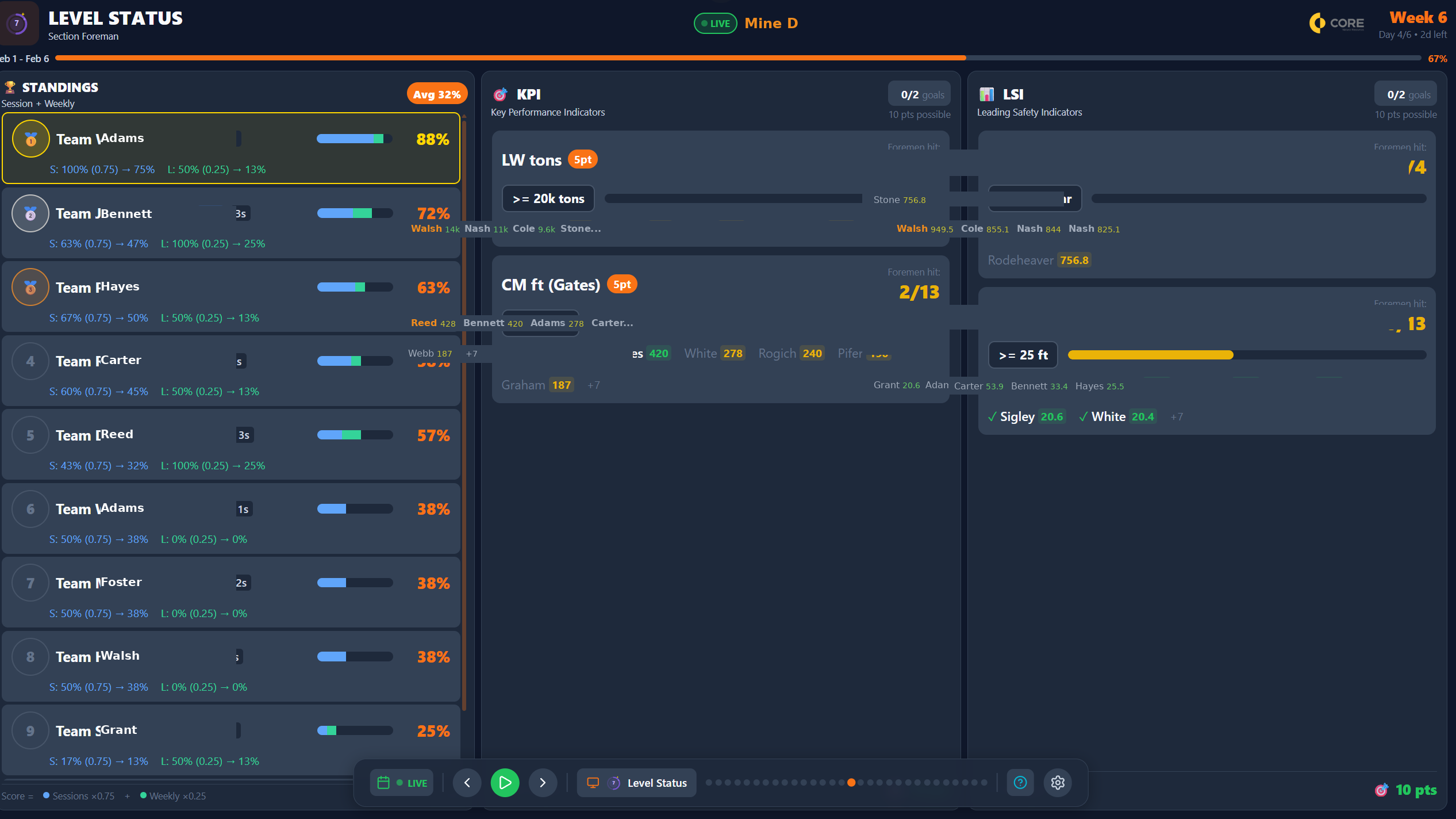

Our clients typically engage us first as consultants. We assess their data maturity, identify the highest-value optimization opportunities, and develop AI algorithms against their actual process data. When the findings are compelling enough to warrant a permanent system — which they usually are — we deploy TSAI and Performa as the operationalization layer. The consulting engagement funds itself through the performance improvement it uncovers.

Currently deploying across 11 active sites at a major US coal producer — prep plants and mines across four states.

We live comfortably in both the time-series world and the traditional data warehouse world. We design and deploy SQL Server and PostgreSQL data warehouses, SSAS tabular models, and integrated datasets that bring together SCADA, ERP, lab, and shift data. TSAI handles the real-time sensor layer. The data warehouse handles everything else. They work together.

Our Philosophy

Start Small

Few large initiatives succeed. Small seeds grow strong roots.

Use What Works

We have an excellent legacy of analytics. Use known standards.

Follow Through ASAP

Flow through the entire data-to-action process as fast as possible. Start using data.

Use Brings Accuracy

The most used data is the most accurate. Don't wait for perfection before acting.

Engage the Workforce

Through detailed feedback, they'll value the data more.

Avoid the Hype

Consultants and tech companies often overhype. Rely on what works.

Founder

Dr. Sean Dessureault, Ph.D. — Mining Engineer, Serial Entrepreneur, Former Tenured Professor

Experience

30+ years in industrial data analytics, mining AI, and operations intelligence

Recognition

American Mining Hall of Fame — "Medal of Merit under 40" · TEDx Speaker · Chair of International APCOM Council

Prior Roles

VP Technology & Innovation, Mosaic Company · Chief Innovation Evangelist, MST Global · Founder & CEO, MISOM Technologies (acquired by Komatsu) · Associate Professor, University of Arizona

Education

Ph.D. & M.Sc., Mining Engineering — University of British Columbia · B.Eng., Mining Engineering — McGill University

Active Deployments

11 sites — PA, WV, CO, WY

Commodities

Coal preparation · Metal mining · Mineral processing · Phosphate & potash · Industrial operations

Time-Series Stack

QuestDB · Node-RED · OPC-UA · MQTT · Redpanda · FastAPI · React · Docker

Warehouse Stack

SQL Server · SSAS Tabular · PostgreSQL · PowerBI · Excel-DNA · C#

Research

$4.5M+ in funded research · PhD and Master's student supervision · Published extensively in mining technology and sustainability

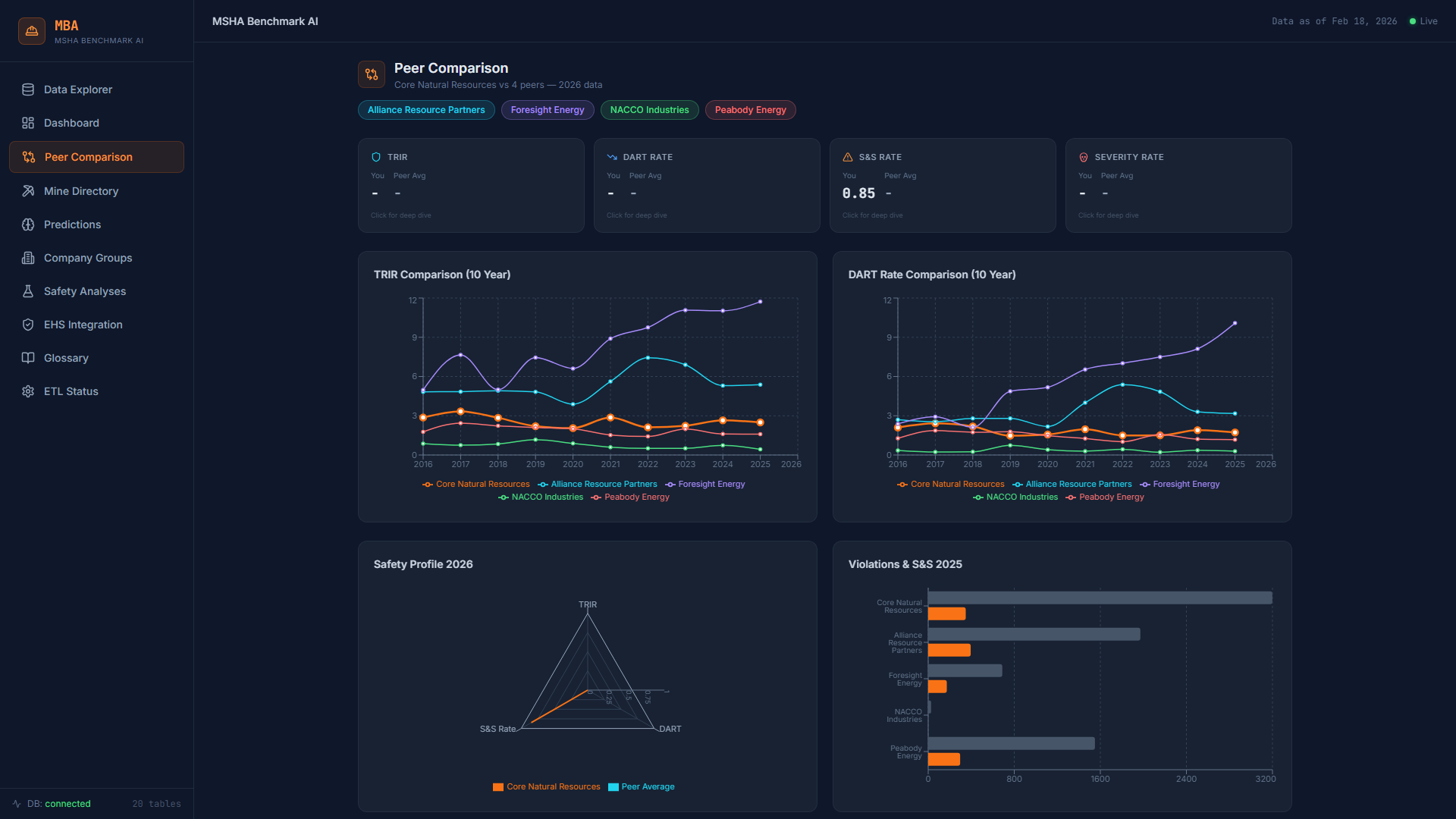

Current Focus

LLM integration for shift reporting, MSHA Benchmark AI, Process Health Monitoring